Последние Новости

09

апреля

Airtech Acquires Kimya Assets to Extend Additive Manufacturing Filament Capabilities and Solutions

09 Apr, 2025

HUNTINGTON BEACH, CA – April 8, 2025: Airtech Advanced Materials Group is pleased to announce the in

04

декабря

Airtech and KraussMaffei Announce Qualification of Dahltram® Resins on powerPrint Large-Format Additive Manufacturing Platform

04 Dec, 2024

HUNTINGTON BEACH, CA – December 03, 2024 : Airtech Advanced Materials Group proudly announces the qu

29

октября

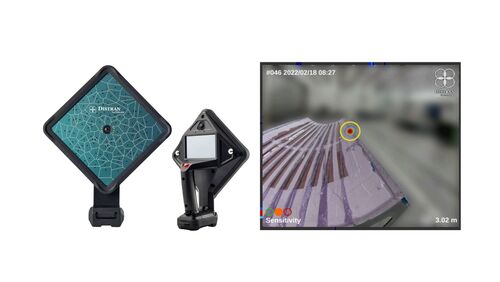

Airtech and Distran Partner to Bring Advanced Leak Detection Technology to the Composites Industry

29 Oct, 2024

HUNTINGTON BEACH, CA – October 30, 2024: As a leader in composite manufacturing solutions, Airtech i

09

сентября

Airtech and Ascent Aerospace Partner to Accelerate Additive Manufacturing Tooling Adoption in Aerospace and Defense

09 Sep, 2024

HUNTINGTON BEACH, CA – September 10, 2024: Airtech Advanced Materials Group, the industry leader in

19

марта

Airtech Advanced Materials Group and Additive Engineering Solutions Partner to Grow Large Format Additive Manufacturing Applications

19 Mar, 2024

SPRINGFIELD, TN & AKRON, OH – March 11, 2024 : Airtech Advanced Materials Group, the industry le

05

марта

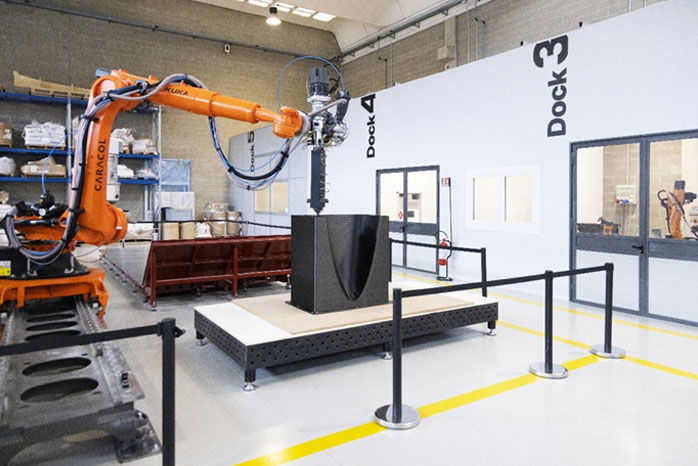

Airtech And Caracol Announce Their Partnership To Grow The LFAM Market With Dahltram® Resins And HERON AM Technology

05 Mar, 2024

HUNTINGTON BEACH, CA – March 06, 2024 : Airtech Advanced Materials Group announces its strategic par

08

ноября

Airtech Redefines Large-Scale 3D Printing with Sustainable Dahltram® T-100GF Resin Debut at Formnext 2023

08 Nov, 2023

HUNTINGTON BEACH, CA – November 08, 2023: Airtech Advanced Materials Group is proud to announce the

02

ноября

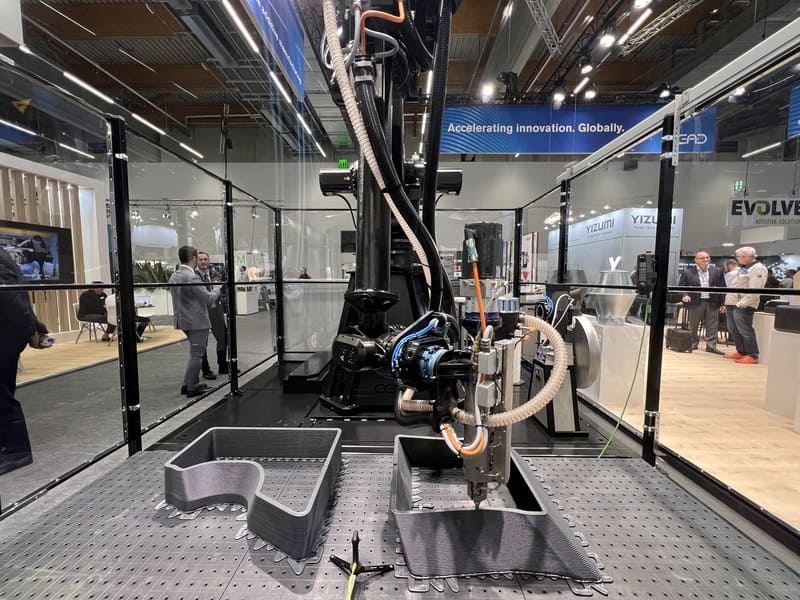

Airtech Advanced Materials Group Unveils Game-Changing Partnership with CEAD

02 Nov, 2023

Cutting-edge 3d Printing Technology To Revolutionize Precision Manufacturing

15

мая

Airtech Advanced Materials Group Celebrates 50th Anniversary with a New Location in India

15 May, 2023

HUNTINGTON BEACH, CA – May 15, 2023: Airtech Advanced Materials Group, a leading provider of innovat

01

ноября

Tygavac Advanced Materials Announces Name Change to Airtech Advanced Materials UK

01 Nov, 2022

CHADDERTON, UK – November 01, 2022: Airtech Advanced Materials Group, the largest privately owned manufacturer of vac

Categories